SA reaches half-way mark in first multibillion-dollar Hunter frigate warship build

Close to 2000 South Australians are now building the first Hunter Class frigate at the Osborne shipyard, constructing the warship like Lego, piece by piece. Business Insight speaks to BAE Systems’ build director to delve into construction details.

Around 1800 workers were now halfway through construction of the first of six Hunter Class frigates to be built at Osborne.

BAE Systems Acquisition and Build Director Andy Coxall told InDaily the project was on track, with construction set to be completed mid-2032 as agreed with the Federal Government.

The first warship to be built by defence giant BAE Systems at Osborne under a Commonwealth Government contract was being put together like a huge, complicated Lego set.

Once that first ship was completed, the growing team at Osborne would already be constructing the second, set to be finished about 18 months after the first. The third would be finished another 18 months after that, a fourth 18 months later, and so on.

It’s a monumental effort that required a major re-skilling program for South Australian workers, thousands of tonnes of steel and a global knowledge-sharing program. But with shipbuilding restarted at Osborne, a continuous shipbuilding program was being cemented at Port Adelaide.

This was imperative, considering the upcoming AUKUS nuclear submarine building program that would also be happening at the Osborne site.

While Coxall said there were about 1800 people at Osborne currently working on the project, that would increase by another 500 people over the next six to 12 months. There were also hundreds of engineers and support staff working interstate along with about 250 people in the United Kingdom working on the project.

You might like

“It’s actually an international effort,” Coxall said.

Coxall said the frigate was more advanced than the British model it was based on thanks to Australian additions – and was designed for anti-submarine warfare. It would be one of the most advanced of its kind in the world once completed, with the Navy claiming “high levels of lethality and deterrence”.

It would incorporate Australian-developed tech and interfaces, including ones made by Saab Australia, and modified to operate the MH-60R Seahawk Romeo helicopter. Weapons on the ship included torpedoes, guns, missiles, and precision kill weapons systems.

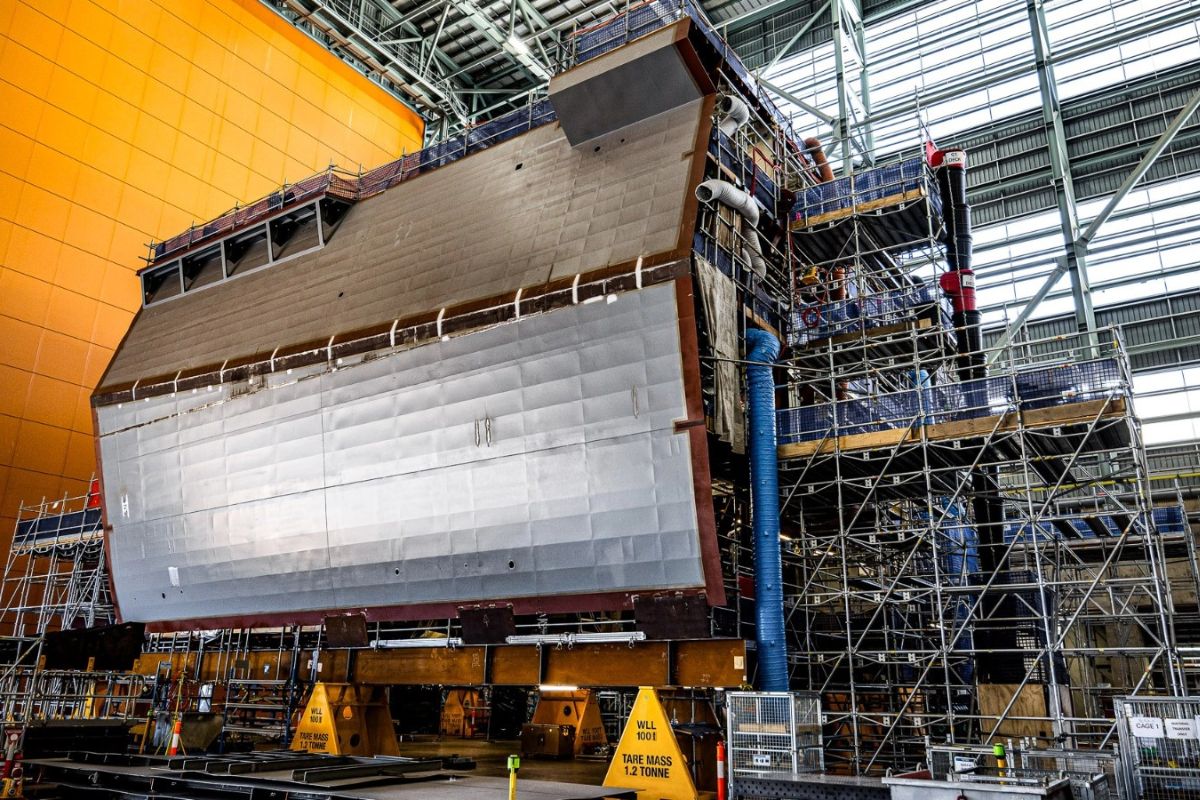

Workers would build the ships like a Lego set, Coxall said, with one ship made up of 78 units, which form 28 ‘blocks’ that were then put together to form one ship.

First steel was cut in mid-2024, and workers had started work on 41 of the 78 units since then. The frigates would be made of 80 per cent Australian steel – 5000 tonnes of it per ship.

“Effectively, in big handfuls, we’re about halfway through the first ship in terms of fabrication,” Coxall said.

But the steel fabrication part of the shipbuilding process was “not the most difficult part”. That comes later when integration of complex systems – cooling, ventilation, fuel systems, communications, weapons – kicks off.

“We are on track for delivery on time or slightly before time, and we’re on budget,” Coxall said.

Stay informed, daily

“We’ve made a good start to the program and the customer (the Federal Govenrment) is watching us closely because they desperately need these ships, given the geopolitics of the region and the fact that this ship is a purpose-built, dedicated anti-submarine vessel.”

This was a capability the Navy had not had in the past, but with submarine warfare “one of the major threats” to Australia, the Hunter Class frigates could not be more timely, Coxall said.

The regular delivery time of the six frigates was “as much connected to maintaining a workforce future here in shipbuilding in Osborne as it is to the capacity of the yard”, Coxall said.

“When the government made the decision to invest here and create continuous naval shipbuilding, it was never just about building ships,” he said.

“It was always about creating a consistent capability and jobs, predominantly in Adelaide, for the foreseeable future.

“That gets us out of the trough of air warfare destroyers being finished, everyone loses their jobs, suddenly a new program starts and we have to re-hire all over again.”

BAE hired staff across every discipline, he said: “We’re employing people who sweep the floors right through to very highly-trained naval architects and weapon systems engineers”.

“We’ve got engineers, project managers, commercial people, accountants, all of the trades from boilermakers, welders, carpenters, electricians, leading into project managers, HR professionals… the whole gamut,” he said.

The Federal Government hoped construction on the first SSN-AUKUS nuclear submarine at Osborne would begin by the end of this decade.

This would involve tripling the size of the shipbuilding facility at Osborne and the hiring more workers.

“We’re forming a foundation for not just our own program but all future programs going forward,” Coxall said.